7500T Extrusion Machine

7500MT Hydraulic Aluminium Extrusion Press Machine for Extruding Aluminum Profile

This Hydraulic Aluminum Extrusion Machine integrates cutting-edge extrusion technology from both domestic and international sources. It features a well-designed structure and an attractive appearance. With a high degree of automation and rapid operation, the extrusion machine allows for easy switching between automatic and manual modes. Key features include an independent mold locking mechanism, a missing cake extrusion protection device, a constant speed function, and a prestressed frame structure. The Aluminum extrusion equipment delivers reliable performance, exceptional production efficiency, and low energy consumption.

Item NO :

7500T Aluminum Extrusion machinePayment :

TTBrand :

HuananColor :

customizableShipping Port :

GuangzhouProduce time :

6 to 10 monthsMaterial and specifications of main parts

|

Item |

Specification & Materials details |

|

Billet size |

Φ460* L600-1600mm |

|

Master cylinder: |

35# forged steel |

|

Piston: |

Φ1740mm 20MnMo forged steel cladding 2Cr13 steel strip |

|

Auxiliary cylinder: |

Φ450/320mm |

|

Container cylinder: |

Φ320/200mm |

|

Front beam: |

1950mm thick, ZG35Mn |

|

Outlet: |

short axis 620mm x long axis 780mm |

|

Rear beam: |

1800mm thick, ZG35Mn |

|

Slider base: |

Ø960X1015 45# steel |

|

Tie rods: |

Φ500mm 42CrMo |

|

Insulation seat: |

ZG35 |

|

Container outside cover: |

5CrMnMo forged steel heat treatment |

|

Container liner: |

H13 Forged Steel Heat Treatment |

|

Stem : |

H13 Forged Steel Heat Treatment |

|

Dummy block: |

H13 forged steel heat treatment |

Advantages of short-stroke back loading structure

1. The short-stroke extruder features a shorter extrusion stroke compared to conventional extruders, resulting in a reduced frame opening and increased stress frame rigidity by 30%.

2. The main side cylinder's volume has been minimized, decreasing hydraulic oil usage and enhancing speed and pressure control accuracy. This design shortens the pressure build-up and release times, lowers energy consumption, and reduces the impact of oil during pressure relief.

3. By eliminating the gasket circulation system, reactive operation time is decreased, and the production line's power consumption is reduced, cutting non-extrusion time by 15%.

4. The use of a servo motor-driven translation manipulator further reduces non-extrusion time by an additional 15%.

Application Field

1.Construction Industry

2.Industrial Trade

3.New Energy Industry

4.Photovoltaic Industry

Our hydraulic aluminum extrusion machine is versatile and finds application across diverse industries. Aluminum profiles produced by this machine are essential for roofs, walls, doors, windows, frames, lattice shell structures, grid systems, glass curtain wall supports, awnings, pedestrian bridges, interior and exterior decorative panels, partitions, ceilings, suspended ceilings, railings, and handrails in both industrial and civil buildings. Additionally, these profiles are integral to constructing materials, structural components, storage containers, and formwork, delivering consistently favorable outcomes in construction projects.

Technical Characteristics and Specification

Technical Date

| 7500MT Technical Parameters | |

| 1.Standard Billet Size: | |

| Outer diameter: |

Φ460mm |

|

Length: |

600-1600mm |

|

2.Extrusion capacity : |

|

|

Machine extrusion force: |

75MN |

|

3.Die Size: |

|

|

Diameter: |

Φ960mm |

|

Depth: |

H1015mm |

|

4.Equipment dimension |

|

|

Mechanical size: |

|

|

Overall weight: |

|

|

Total Power: |

1600KW |

|

5.Motor |

|

|

Main oil pump: (Hilectro brand) |

HP130U2-G102W*10 |

|

Liquid cooling driver |

Hi200-180KW *10 |

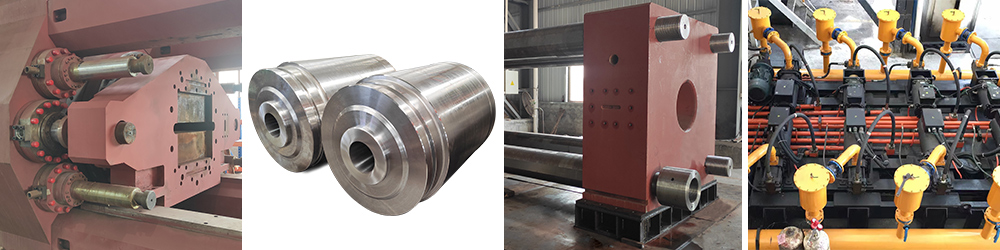

Shipment Pictures

Workshop show

FAQ

Q1: How is the quality of Huanan Brand machine and the service life?

Huanan Brand is one of the best equipment for extrusion manufacturers in China. According to the feedback of old customers, under normal circumstances, the life of the machine can reach 15 years or more. Many well-know aluminum manufacturers are also our cooperative customers.

Q2: How to choose the right type machine ?

Please let us know the types of products you manufacture. Provide the dimensions of the profile sectional drawing, and we will calculate the appropriate machine size based on your specifications.

Q3. Will Huanan provide installation service?

Upon delivery of the aluminum extrusion machine to the customer's factory, and once installation conditions are met, we will dispatch technicians to the site to install the machine and train the customer's employees on its proper operation.

Q4:What is the delivery time of Huanan Machines?

For ordinary small-sized machine such as 600-1000MT, 30 days; middle-sized machine such as1250-1800MT, 45-60 days, for big-sized machine such as 2000-3000MT, 180 days.More than 3000MT, half year to one year delivery date. We could also design and make the whole production line for our customer, around 3-10 months.

Q5: What services Huanan can do for you :

Huanan offers comprehensive one-stop services, covering pre-sales, sales, and after-sales support:

Copyright @ 2025 Huanan Heavy Industry Technology Co.,Ltd All Rights Reserved. Network Supported

Network Supported

Sitemap / Blog / Xml / Privacy Policy