600T Extrusion Machine

Huanan automatic extrusion press machine combines the advanced technology of the extrusion industry at home and abroad, the overall structure is reasonable, the appearance is beautiful, the degree of automation is high, the speed is fast, the automatic and manual switching is easy to operate, it is equipped with an independent mold locking device, missing cake extrusion protection device, constant speed, prestressed frame structure, etc., reliable performance, high production efficiency, and low energy consumption.

Item NO :

600T/660UST Aluminium Extrusion Press MachinePayment :

T/TBrand :

HuaNanColor :

CustomizeShipping Port :

Guangzhou/ShenzhengProduce time :

3 monthsWeight :

26TDimension :

L7000mm×W2900mm×H3200mmMaterial and specifications of main parts

|

Item |

Specification & Materials details |

|

Master cylinder: |

35# forged steel |

|

Piston: |

Φ580mm alloy chilled cast iron |

|

Auxiliary cylinder: |

Φ140mm 2 pieces |

|

Container cylinder: |

Φ140mm 4 pieces |

|

Front beam: |

350 mm thick, material: 45# forged steel |

|

Outlet: |

short axis 140mm x long axis 120mm |

|

Slider base: |

thick 200mm 45# steel |

|

Movable beam: |

thick 200mm 45# steel |

|

Tie rods: |

Φ155mm 45# steel quenched and tempered |

|

Insulation seat: |

ZG35 |

|

Container outside cover: |

5CrMnMo forged steel heat treatment |

|

Container liner: |

H13 Forged Steel Heat Treatment |

|

Stem : |

H13 Forged Steel Heat Treatment |

|

Dummy block: |

H13 forged steel heat treatment |

Advantages of short-stroke back loading structure

1.Automatic aluminum extrusion press machine, compared to conventional extruders, the extrusion stroke of the short-stroke extruder is shorter, resulting in a smaller frame opening. This modification increases the rigidity of the stress frame by 30%

2.The volume of the main side cylinder has been decreased, leading to lower hydraulic oil consumption. This change enhances both speed and pressure control accuracy, shortens the time needed to increase and release pressure, reduces energy consumption, and minimizes the impact of oil during pressure release.

3.The elimination of the gasket circulation system cuts down on reactive operation time and reduces the power consumption of the production line. Non-extrusion time is decreased by 15%.

4.Utilizing a translation manipulator driven by a servo motor further reduces non-extrusion time by 15%.

Application Field

1.Construction Industry

2.Industrial Trade

3.New Energy Industry

4.Photovoltaic Industry

Automatic aluminum extrusion press machine can produce various aluminum profiles, which are used in roofs, walls, doors and windows, frames, reticulated shell structures, grid structures, glass curtain wall support systems, awnings, pedestrian bridges, interior and exterior decorative panels, partitions, ceilings, suspended ceilings, railings and handrails, and decoration in industrial and civil buildings. Materials and structural components, store containers and formwork for construction are widely used with good results.

Technical Characteristics and Specification

1. The critical components of the automatic hydraulic aluminum extrusion machine (including the container, extrusion pad, shear blade, and ingot feeder) feature mature structures with a low failure rate.

2. This aluminum extrusion equipment exhibits minimal impact and vibration, thus reducing the likelihood of oil leakage.

3. With rapid response times, high efficiency, and minimal non-extrusion periods, the equipment ensures swift operations.

4. Precision is a hallmark of this equipment, boasting accurate extrusion speed control within a range of ±0.1mm.

5. Offering a high degree of automation and intelligent production capabilities, the equipment minimizes the need for operator intervention and maintenance staff, streamlining operations.

Technical Date

| 600MT/660UST Technical Parameters | |

| 1.Standard Billet Size: | |

| Outer diameter: |

Φ90mm |

|

Length: |

500mm |

|

2.Extrusion capacity : |

|

|

Machine extrusion force: |

21Mpa 617T(678UST) |

|

3.Dimensions of mold base cavity: |

|

|

Diameter: |

Φ190mm |

|

Depth: |

H200mm |

|

4.Equipment dimension |

|

|

Mechanical size: |

L7000mm×W2900mm×H3200mm |

|

Overall weight: |

26T |

|

Total Power: |

83KW |

|

5.Motor |

|

|

Main oil pump: (Hilectro brand) |

HP12981-G102W-R1P4 |

|

Liquid cooling driver |

Hi300-90KW |

|

6.Hydraulic pump |

|

|

Main oil pump: (Germany Rexroth) |

A15VSO175 variable pumps |

|

Auxiliary pump:(Tokyo Keiki) |

SQP43-60-38 |

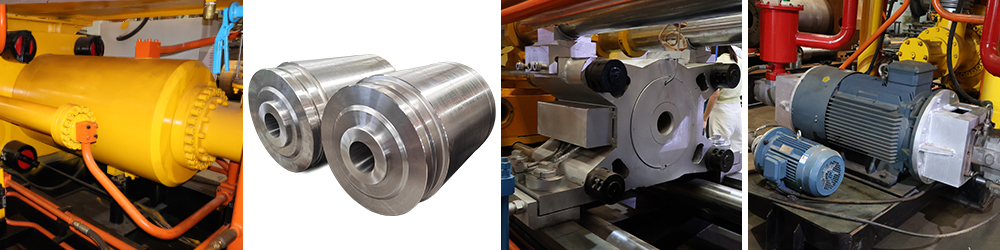

Shipment Pictures

Workshop show

FAQ

Q1: How is the quality of Huanan Brand machine and the service life?

Huanan Brand is one of the best automatic aluminum extrusion equipment manufacturers in China. According to the feedback of old customers, under normal circumstances, the life of the machine can reach 15 years or more. Many well-know aluminum manufacturers are also our cooperative customers.

Q2: How to choose the right type machine ?

Please tell to us what kind of products you make ?Provide the profile sectional drawing dimensions ,we will according your size to calculate the suitable machine size.

Q3. Will Huanan provide installation service?

When the aluminum extrusion machine arrives at the customer's factory and meets the installation conditions, we will send technicians to the site to install it and train customer employees on how to use the equipment correctly.

Q4:What is the delivery time of Huanan Machines?

For ordinary small-sized machine such as 600-1000MT, 30 days; middle-sized machine such as1250-1800MT, 45-60 days, for big-sized machine such as 2000-3000MT, 180 days.More than 3000MT, half year to one year delivery date. We could also design and make the whole production line for our customer, around 3-10 months.

Q5: What services Huanan can do for you :

Huanan will do professional One-station services (pre-sales, in-sales, after-sales service system):

Technical consultation and support;

Making a complete production proposal based on customer’s needs;

Design/manufacturing/inspection/uploading/shipping/all original documents services;

Installation/technology training and support/maintenance in a life time.

Copyright @ 2025 Huanan Heavy Industry Technology Co.,Ltd All Rights Reserved. Network Supported

Network Supported

Sitemap / Blog / Xml / Privacy Policy