This week, we welcomed a client from Spain who is interested in purchasing a copper extrusion press for producing copper materials.

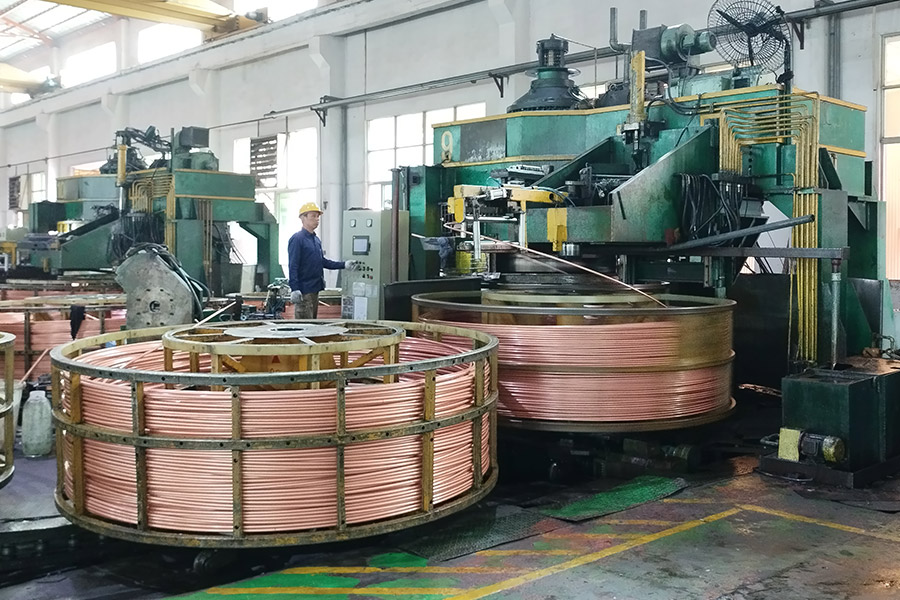

We gave the client a tour of our factory and demonstrated the copper production process. The client was very satisfied with our extrusion machines.

In fact, copper extrusion and aluminum extrusion share many similarities — the production processes and the machinery used are quite alike. However, the heating temperature during the copper extrusion process is different. For pure copper, the typical heating range is 400–500°C; for brass alloys, it's generally 600–750°C. If the heating temperature is too low, it may cause cracking; if it's too high, it can lead to coarse grain structures or severe oxidation.

Additionally, the extrusion die is usually preheated to 200–400°C and coated with graphite, glass powder, or other lubricants. The other stages, such as cooling, stretching and straightening, and surface treatment, are also quite similar to the aluminum extrusion process.

If you're planning to produce specific copper products — such as copper heat exchanger tubes, copper busbars, copper rods, or custom-shaped profiles — we can help you design a more detailed and tailored extrusion process.

Please contact our sales team at:

+86 13450865812

Copyright @ 2025 Huanan Heavy Industry Technology Co.,Ltd All Rights Reserved. Network Supported

Network Supported

Sitemap / Blog / Xml / Privacy Policy